We at Mallett, take advantage of every tool available to model our customers problems in the quickest, most accurate, and cost-effective way. Explicit tools unleash a wealth of possibilities for modeling complex, transient events. Our Ansys® LS-DYNA® and AUTODYN™ solvers are the best in the industry, and our state-of-the-art computing cluster is optimized for Massively Parallel Computation (MPC) using these tools. We leverage our many years of experience and knowledge to quickly and efficiently model your system and provide you with the design insight you need. Our explicit dynamics simulations capabilities include:

- Drop-test analysis

- Ballistic impacts

- Metal Forming

- Explosives

- Soil and concrete interaction

- Foam crushing

- Shockwave propagation

- Material failure – fracture, necking, crushing

- Post-buckling, crumple zones, energy dissipation

The variety of transient phenomena we can simulate is nearly limitless. Contact us to discuss your specific application and needs.

Example Projects

Below are some examples of our analysis projects. These examples have been generalized to protect our clients, and this list is by no means exhaustive. If you don’t see anything representative of what you want to analyze, please contact us and we can provide examples of some of our projects that are similar to your needs.

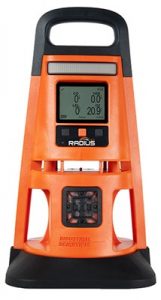

Mining Equipment Drop Simulation

Will the industrial mining equipment survive a fall?

- All contact between parts captured

- Correlated simulation results to test

- O-ring seal analyzed during event

- Resulting plastic damage analyzed

Identified areas where drops could create cracks in the structure.

Drop of Commercial Electronics

Will the electronic device survive a drop event from the specified height at a variety of angles?

- All part to part interaction captured

- Glass failure modeled

- PCB dynamics captured

- System prestressed with assembly loads prior to drop

Identified design limitations. Recommended potential redesign options.

Ruggedized Thermos Drop

Will the thermos, particularly the collapsible handle mechanism, survive drop test?

Project Details:

- Drop and impact onto rigid concrete

- Plasticity (yield) of steel and thermoplastic (nylon)

- Snap detents, hinges, cams, sliders modeled realistically

- Overmolded plastic on steel

Two design risks were identified and characterized for improvement ahead of prototyping and tooling.

Projectile Rifling Band

What projectile band material and geometry results in the best rifle engagement and ballistic performance?

- Ballistic loading

- Material failure and energy dissipation

- High performance computing – many simulation iterations toward optimization

Identified critical parameters for material selection.

Trash Bin Durability Simulation

Will the trash bin withstand the worst case scenarios expected during regular use?

- Transient impact explicit FEA simulation

- Elastic and hyperelastic materials

- Subjected structure to different loading scenarios

Identified a high-stress location prior to prototyping and testing

Mattress Characterization and Simulation

What is the response of the mattress to different kinds of loading?

- Interaction of spring, fabric, and foam components

- Complex viscoelastic materials

- Characterization of all components using test data

- Comparison of different proposed mattress designs

High-rate and quasi-static load correlation and identification of high stress locations

Large Pillow Tank – Military, Desert Fuel Storage

Will the tank perform robustly (pressurization, military application)?

- Transient solution simulates tank inflation from empty to full capacity (diesel fuel).

- Ground interaction (sand or packed earth) and tank wrinkling are captured and accounted for

- Orthotropic fabric with various seams and reinforcements

- Optimize tank footprint versus volume

Tank safety factors meet or exceed all requirements for all load cases.