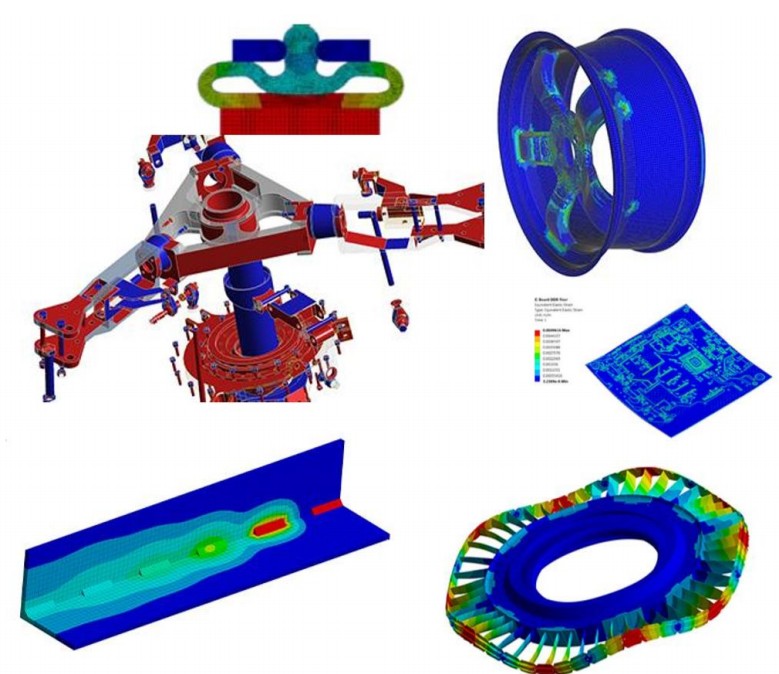

ANSYS Mechanical is a flagship finite element tool for modeling structural and thermal effects. Users are able to solve anything from linear statics to complex transient simulations involving hyper-elastic materials. This is the top of the line tool when it comes to modeling structurs in the implicit world.

ANSYS mechanical provides an easy tree-based user interface that can be utilized by design engineers, product engineers, all the way to full time analysts.

ANSYS Mechanical also has strong two-way connections with ANSYS tools in the electrical, fluids, and systems spaces.

Versions of Mechanical

Mechanical Pro

Mechanical Pro is a finite element analysis (FEA) solution that provides robust general purpose stress, thermal, vibration, and fatigue simulations for fast accurate solutions.

Mechanical Premium

Mechanical Premium is a finite element analysis (FEA) solution that gives you greater engineering insight with advanced nonlinear stress simulations and comprehensive linear dynamics.

Mechanical Enterprise

Mechanical Enterprise is a comprehensive suite of finite element analysis (FEA) solutions that provides in-depth analysis of structural and coupled-field behavior in a highly productive environment for advanced engineering or enterprises with broad structural analysis needs.

Features

Below are a list of some of the features available in ANSYS Mechanical. Note, all these features are available with the Enterprise version, but only a smaller subset will be available with the Pro or Premium versions. Feel free to contact us for help in determining the version you need.

Strength Analysis You can easily configure and solve static and transient analysis, as well as analyze linear and non-linear buckling of parts and assemblies. You can also use Modeling techniques like sub-modeling and substructuring. Geometry Non-Linearity Enables you to capture the change in stiffness caused by loads applied to structures, ensuring that effects like stress stiffening, large strain and large deflections are accounted for. Material Models ANSYS Mechanical has a vast range of material models to capture all manner of materials used in engineering. Material Models: Isotropic/orthotropic elasticity Multilinear elasticity Hyperelasticity Anisotropic hyperelasticity Bergstrom–Boyce Mullins effect Plasticity Viscoelasticity Viscoplasticity Creep Other Models: Cast iron plasticity Drucker–Prager Shape memory alloy Swelling material model Gasket material Concrete Gurson damage USERMAT Contact Modeling ANSYS Mechanical gives you a wide range of options to capture the interactions of contacts or joints between parts of an assembly. You can modify the contact settings and options, and add additional manual contact definitions. The automatic contact generation tool detects and accelerates the creation of contact pairs, include more complex effects like friction, gaskets, load dependent contact as well as fracture methods. Vibration Analysis Modal, Harmonic, Spectrum, Random and Rotordynamic analysis enables you to understand how natural frequencies, forced vibration, seismic and transportation (among others) in different environments might affect structures during the life of your product. Thermal Analysis ANSYS Mechanical helps you perform steady state and transient analysis of your products, including conduction, convection and radiation effect. Its ability to model phase-change and temperature dependent materials ensures an accurate simulation. Motion You can easily simulate mechanical motion by modeling joints, both perfect and imperfect, and define the stiffnesss of bushes and bearings. Being able to switch parts between flexible and rigid behavior allows you to run calculations even faster. Composite Materials ANSYS Mechanical is able to model the complex behavior of composites. You can examine the material definition and first and last ply failure modes, as well as the delamination of layered composites. The addition of ANSYS Composite PrepPost allows complex layer definition and solid extrusion as well as the ability to carry out more detailed post processing. Platform Technologies ANSYS Workbench enables you to take data from other analysis systems and very easily create studies using results from other simulations. You can map data from external files, other mechanical systems or other physics using drag-n-drop Multiphysics. Multiphysics You can use ANSYS Mechanical to analyze the interaction of different physics phenomena and better simulate real world conditions. ANSYS Mechanical supports the following types of interactions: Geometry and Meshing You can use existing native CAD geometry can be used directly with ANSYS structural analysis software — with no translation, no IGES and no intermediate geometry formats. ANSYS has provided native bidirectional integration with the most popular CAD systems for more than a decade. Integration directly into the CAD menu bar makes it very simple to launch world-class simulation directly from a CAD system. HPC Today’s computing environment gives users access to more power than ever before. Tasks like contact detection, mesh generation and solving all benefit from the additional, and ever increasing, core counts seen in today’s computers. Parallel mesh generation reduces the time it takes to having solver ready models drastically and this in turn with the speed ups in contact detection Solver Capabilities ANSYS structural analysis software offers a large library of out-of-the box equation solvers. The library contains the sparse direct solver, preconditioned conjugate gradient (PCG) iterative solver, Jacobi conjugate gradient (JCG) solution and more. In addition, the distributed versions of PCG, JCG, and sparse solvers are available for use in large-scale computing via parallel processing. By combining our parallel algorithms with the power of GPUs, you can further reduce the solution time required for large models. Variational technology from ANSYS allows accelerating computation of normal modes for cyclic structures, especially when a large number of harmonic indexes are required. Frequency sweeps such as those found in harmonic analyses benefit from variational technology as well. Typical speedup factors range from three to 10 times. Transient thermal runs and certain classes of nonlinear structural transient problems are computed in a shorter time using these same principles. Reporting You can explore a design in multiple ways and efficiently document the results. ANSYS structural analysis software provides instantaneous report generation to gather all technical data and pictures of the model in a convenient format (HTML, Microsoft® Word or Microsoft® PowerPoint®) Element types. The current generation of ANSYS element technologies provides rich functionality with a consistent theoretical foundation coupled with the most advanced algorithms. ANSYS structural analysis software provides a large library of elements including beam, pipes, shells, solids, 2-D planar/axisymmetric and 3-D axisymmetric elements, which have wide applicability that includes composites, buckling and collapse analysis, dynamics analysis and nonlinear applications. The library also includes special-purpose elements like gaskets, joints, interface elements and layered elements for composites structures. These elements offer superior performance and functionality. They also support advanced material models and methods like remeshing/rezoning, fracture mechanics and coupled fields while also accommodating distributed solver processing needs.

Results can have matching meshes or you can accurately interpolate them on to a new mesh.. You can also take take 2-D data and map it onto compatible 3-D models using the automated tools inside the Workbench platform. You can use ANSYS Mechanical to compute in a fully coupled manner or by using co-simulation approaches.

Solver

Type

Direct

Sparse

Iterative

PCG

Distributed Memory

Dsparce/DPCG

Solid Elements

Coupled-Field Elements

Special Elements

2-D quad/tri

Pore pressure elements

Rebars/reinforcements

3-D

Fluid-thermal

Links/pipes/elbow

hexa/tetra/wedge/pyramid

Magnetostructural

Springs/joints

Layered solids

Thermal-electric

Cohesives zones

Solid Shell

Hydrostatic fluid elements

Gaskets

4-node tetra (stabilized)

User elements

Shell Elements

Beam Elements

Lower/higher order

Multi-material beam analysis

Layered Shells

Beam cross section definition